CNC Turning Service

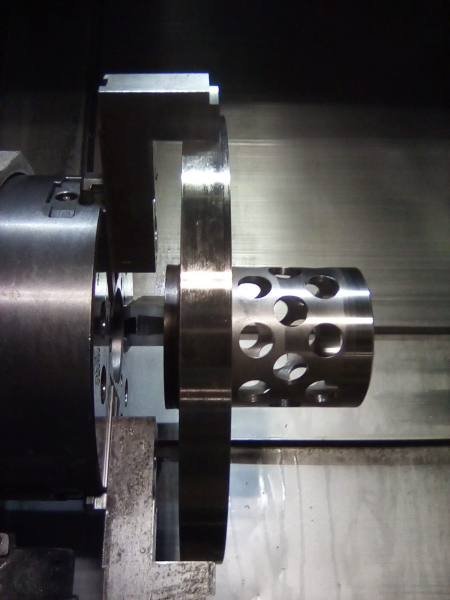

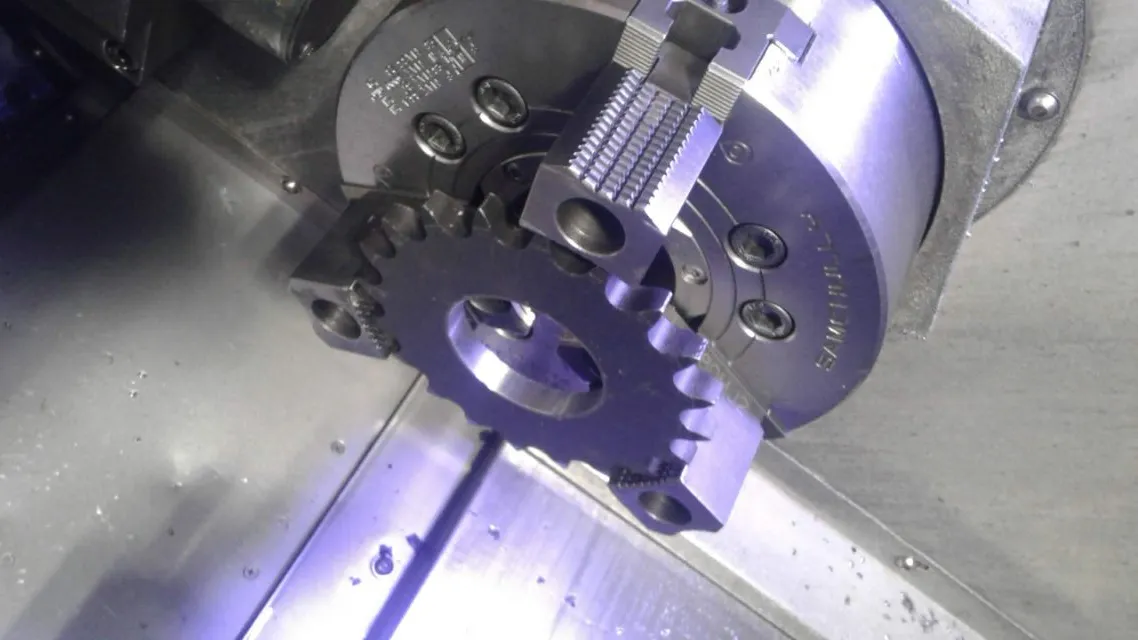

At RDL Machine, we offer top-notch CNC Turning Services to manufacture precision components and assemblies using innovative turning centers and ISO 9001 and AS9100D certified processes. Our skilled machinists use computer-automated lathe machines for precise repeatability, catering to low to high-volume runs while tailoring each process to meet your unique project requirements.

Learn more about our CNC lathe machining and turning capabilities below, Contact us for more information or Request a quote and let us get started on your next CNC turning project.

Benefits of Precision CNC Lathe Machining & Turning

Improved Accuracy

Our CNC lathe machining centers can maintain tolerances up to +-0.0005 inches, ensuring precision components made to your exact specifications.

Hyper-Efficient

With high material removal rates and rapid throughput, our CNC turning centers efficiently handle small to high-volume tasks, reducing errors and allowing for highly repeatable processes.

Endless Applications

Our CNC machining capabilities cover components of various sizes and shapes, including heavy-duty ones. We use ISO 9001 and AS9100D certified processes to ensure compliance with industry regulations and work with diverse metals and hard-to-machine alloys.

RDL Machine CNC Turning Center Machines

QUICKTURN QTS 250: Travel Distance X-axis 190 mm (8.75 in), Travel Distance Z-axis 515 mm (20.25 in), Max Turning: Diameter (13.78 in), Length (18.73 in), Max. Bar Work Capacity (3 in), 35 Hp, 4000 rpm, 12 slot turret station.

DOOSAN PUMA GT2600L: Travel Distance X-axis 265 mm (10.4 in), Travel Distance Z-axis 1100 mm (43.3 in), Max Turning: Diameter (18.1 in), Length (42.4 in), Through Hole (3.2 in), 30 Hp, 3500 rpm, 12 slot turret station.

DOOSAN PUMA GT2100: Travel Distance X-axis 230 mm (9.1 in), Travel Distance Z-axis 580 mm (22.8 in), Max Turning: Diameter (15.4 in), Length (22.2 in), Through Hole Diameter (2.6 in), 25 Hp, 4500 rpm, 12 slot turret station.

DOOSAN LYNX 2100 LSY

Advanced Precision CNC Lathe Turning Services for Any Industry

Our state-of-the-art machines, equipment, and programming software enable our experienced machinists to fabricate intricate projects with high precision and cost-efficiency. We serve various industries, including Medical, Aerospace & Defense, Oil & Gas, Automotive, and Job Shops.

Why Choose RDL Machine For CNC Turning Services

As an industry-leading machine shop of over 20 years, RDL Machine has the experience needed to provide quality and cost-effective CNC machining for virtually any requirement. Our ISO 90001 certified processes ensure precision, efficiency and customer satisfaction is achieved in a timely manner. We use CMM measuring technology to produce accurate, high-quality components that can’t be matched by our competitors.

Our highly skilled programmers and machinists collaborate to combine elements of mechanical design, blueprints, and mathematics to yield products that meet precise specifications. By taking a component from design to completion, we can monitor the quality of a part at various stages for improved quality and reduced turnaround times. We also employ state-of-the-art computer programming software such as Solidworks and Master cam to quickly create complex custom components based on your exact designs. Furthermore, we offer secondary services to further customize or finalize your project.

Contact Us for CNC Turning Services

You can trust us to get the job done right in the timeline you need. Contact us or request a quote to discuss your requirements with our CNC turning experts.